Lean- The background for Lean is

very simplistic and yet can also be difficult to grasp, it involves the use of common sense. These principles go as far back as Poor Richard's Almanac in which Benjamin Franklin wrote

"Save and have". As time went

on more and more concepts were driven into the work place. Frank Gilbreth

tripled the swiftness in which a mason could build a house. Later Henry Ford

took his turn at creating a productive industry, My Life and Work(1922) is a single paragraph in which Henry Ford

very aptly describes the concept of waste.

" I

believe that the average farmer puts to a really useful purpose only about 5%

of the energy he expends.... Not only is everything done by hand, but seldom is

a thought given to a logical arrangement. A farmer doing his chores will walk

up and down a rickety ladder a dozen times. He will carry water for years instead

of putting in a few lengths of pipe. His whole idea, when there is extra work

to do, is to hire extra men. He thinks of putting money into improvements as an

expense.... It is waste motion— waste effort— that makes farm prices high and

profits low."

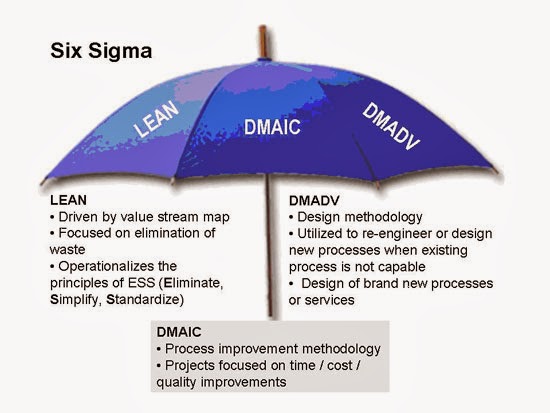

Six Sigma- Six Sigma is not as simplistic as the concept

of Lean, but that may be because of its sheer specificity. Six Sigma in order to ensure that proper

techniques are practiced has a very specific set of doctrines and other methods

that accompany it. The basic doctrine is

to use continuous effort to achieve predictable

and stable results. These efforts

must constantly be analyzed and organized to help ensure that the whole process

works as smoothly as possible as much of the time as it can. A company is like an enormous clock, it will

only work if all the little clogs mesh together. There are two methodologies which help this

"machine" stay in working order, duh-may-ick (DMAIC) and duh-mad-vee

(DMADV). Each of these are a set up of specific acronyms that are fitted to a

specific purpose. First you define the voice of the customer and therefore the

goals you want this machine to achieve. Secondly, you must measure the capabilities of

the machine: product capabilities, production outputs, risks, and other

relevant data. Third, there must be analysis in order to create new methods

or alternative strategies in the most productive manner to be rid of any and

all defects. Either design or improve is the next step in which the analysis is

looked over and the process is either recreated or replaced to make it more

efficient. Lastly, verify or control to ensure that the process

remains as capable as possible and no defects will arise in the future.

"Integrating Lean and Six Sigma." BPMInstitute.org. N.p., n.d. Web. 15 Feb. 2014.

"Integrating Lean and Six Sigma." BPMInstitute.org. N.p., n.d. Web. 15 Feb. 2014.